Professional 3D scanning

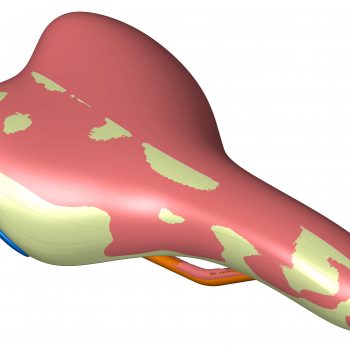

The design process starts with a professional 3D scan, joining craftsmanship tradition and modern technology; the challenge was designing a new bicycle saddle from a customer-supplied wooden prototype sculpted by an artist.

Starting from a physical model, often hand-made by skilled craftspeople, the team of TECNOLOGIA & DESIGN scans the model in order to reconstruct it faithfully and adapt it to the technical specifications for the manufacture of this product.

Every aesthetic detail, as well as all the standard mechanical details, was developed in conjunction with the customer, in order to create a new product that can address the market needs.

From real to virtual objects

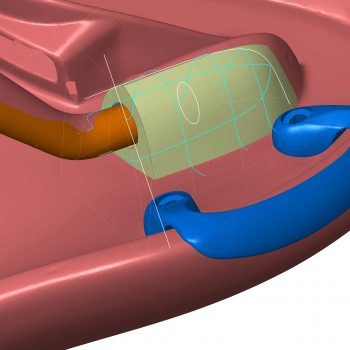

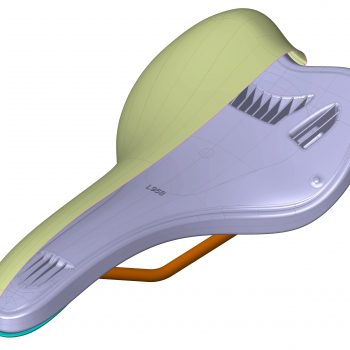

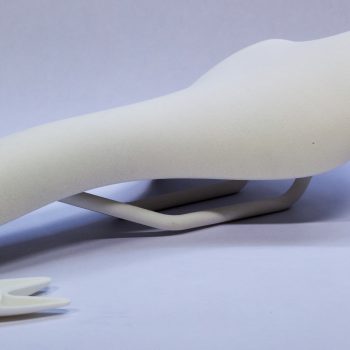

Shapes and symmetries were created in collaboration with a designer, followed by all the control and analysis phases; prototypes for all pieces were manufactured in our in-house 3D printing department, so as to be able to touch what a moment ago was only a virtual representation. This made it possible to check and assess the final product, and then quickly make the necessary adjustments, thanks to specific 3D CAD software products, to have a final confirmation for the subsequent production phase, in which the mould was designed and manufactured.

A clear instance of modern design techniques meeting traditional techniques, to endow the new product with considerable added value.

Step by step, the Saddle bicycle saddle went from a hand-crafted prototype to a mass market object, by means of professional 3D scanning, SolidWorks checks and analyses and rapid prototyping by means of 3D printing.